No products in the cart.

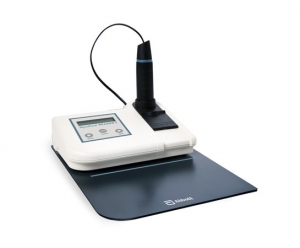

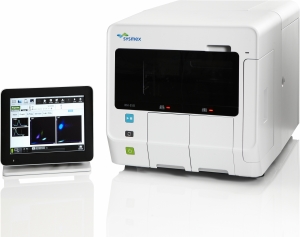

Afinion™️ 2

The Afinion™️ 2 Analyzer enables fast and easy quantitative determinations of HbA1c, Lipid Panel, ACR and CRP with lab equivalent accuracy and precision, certification from NGSP/IFCC/CRMLN, and self-check systems to eliminate erroneous results. From just a finger stick sized sample, lab accurate results for CRP, HbA1c, ACR and Lipid Panel