CONTACT US

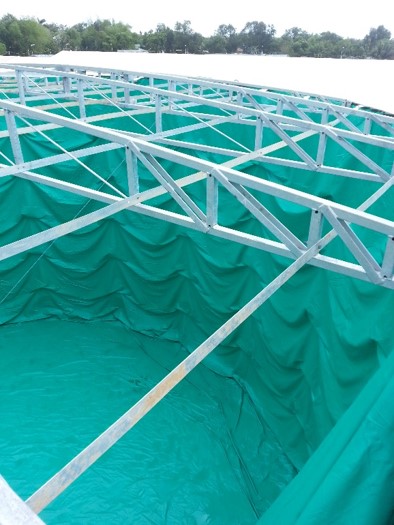

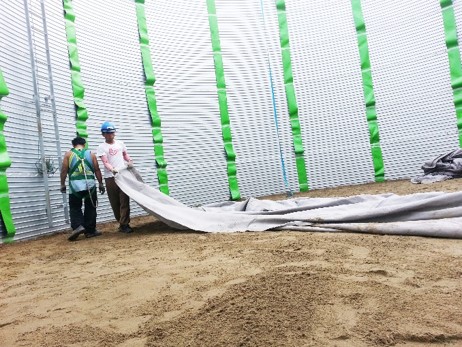

- WATERCO Filters

- WATERCO is based on Australia and at the forefront in the design and manufacture of fiberglass filters.

- WATERCO fibreglass filters embody the latest in fibreglass winding technology.

WATERCO’s computerised digitally controlled filament winding machine faultlessly winds continuous strands of fibreglass filament to create a filter vessel with refined consistency and superior quality.

- The design and the manufacturing process utilising the most up-to-date filament winding machine, incorporation of non-metallic fittings plus reinforcing manhole openings with proprietary methods.

- WATERCO fibreglass filters are perfectly suited to the constant increases and decreases in pressure experienced by sand filters. Accelerated cyclic testing has shown that even after a simulated use of 20 years, WATERCO fibreglass filters withstood cyclic wear and tear better than most other filters in their class.

- Reverse Osmosis System

- Compact Type

(150 GPD up to 400 GPD)

Included:

- 5 Micron Prefilter

- 1 Micron Prefilter

- Carbon Block Prefilter

- Anti-Scalent Prefilter

- Booster Pump

- RO Membrane

- Commercial Type

(300 GPD up to 16,000 GPD)

Included:

- Stainless Steel Frame

- Stainless Steel or Fiber Glass Membrane Vessel

- Anti-Scalent Device

- Stainless Steel Vertical Pump

- RO Membrane

- Fine Filtration

A sediment filter acts as a sieve to remove the

particles in water which can disturb the performance

of equipment in water treatment system such as

Reverse Osmosis, Filters and so on.

AQUAPRO Fine Filtration

- Stainless Steel Filter Housing

- Easy to remove Cartridges for

maintenance or replacement

- Resist to high pressure

Category: Water Treatment System