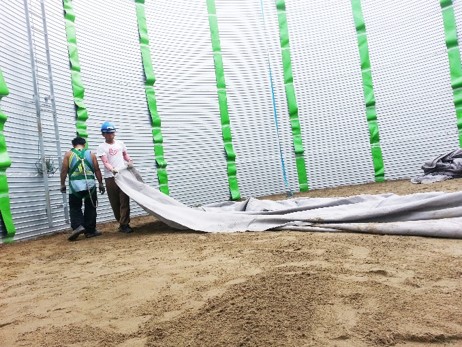

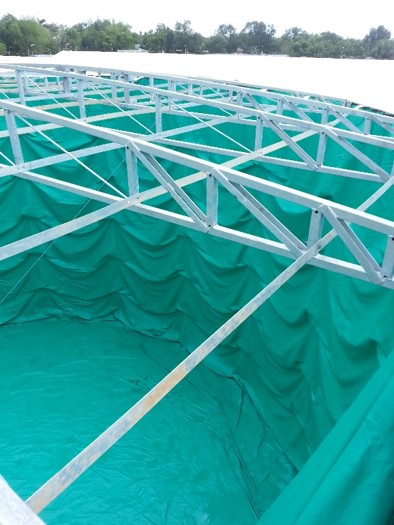

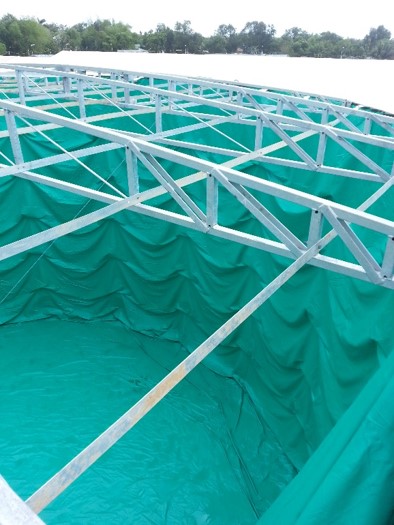

When Coca Cola returned to Myanmar after a long absence, they took over a site used to manufacture local soft drink brands. Due to the requirement for quick expansion they ordered an extremely large prefabricated steel zincalume coated tank from Amd for raw water storage. Further requirements included the need for seismic rating in the event of Earthquakes or Tremors. Amd added a special Antivortex fitting required to meet firefighting codes. Once on site the 640m3 tank was installed in nineteen days including the erection of the necessary scaffolding.

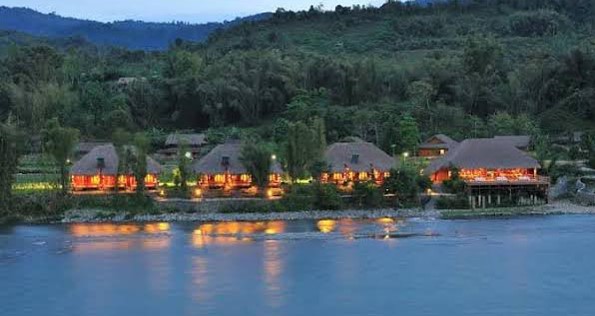

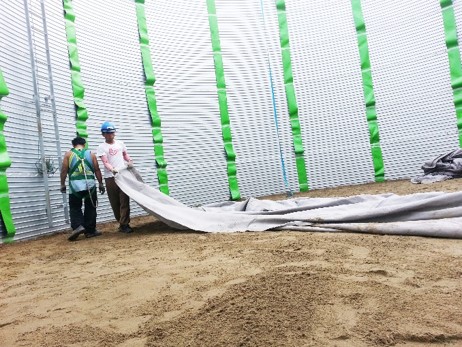

Domestic waste water Coca Cola

The need to properly treat wastewater from a site employing four hundred people was recognized early in the design process. Amd retrofitted a large fiberglass packaged plant featuring several pump stations. The job was complicated by the existence of an old Septic system within the site. Amd has further recommended that post effluent treatment would expand the options for disposal of the treated effluent. Post effluent treatment involves filtering the treated wastewater via several filters and adding ultra-filters if the water is for reuse. This step can be taken any time after initial installation.